|

|

|

|

Advanced Metallurgical Coatings, Inc - PVD (Physical Vapor Deposition) Coatings |  |

| Welcome To AMC's homepage for PVD Coatings What is PVD? Simply this can be defined as Physical Vapor Deposition and can encompass various technologies such as CAPVD (Cathodic Arc Physical Vapor Deposition), Sputter Ion Plating, and EBPVD (Electron Beam Physical Vapor Deposition.) |

|

|

| Tooling Applications Where has PVD found its principle applications? It works very well in low and moderate temperature applications - for coating cutting tools - such as high speed steel drills, hobbs, saw blades, dental tools, etc. (This technique has displaced CVD for coating of non-tungsten carbide cobalt cutting tools because CVD requires a temperature typically greater than 700 deg. C - and more typically in the 980 - 1038 deg. C. Range. |

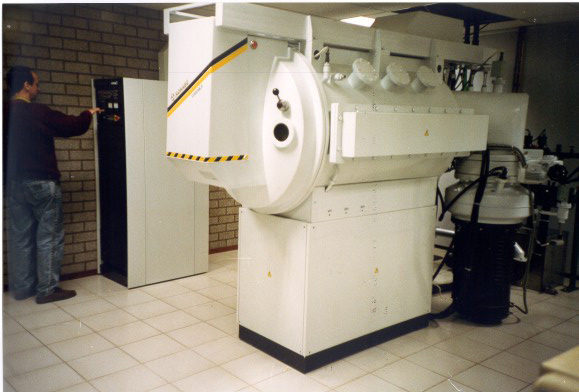

Sidrabe's PVD System Example This system can be configured as either a CAPVD or SIP system. |

|

Aerospace Applications Decorative Coatings |

Sidrabe of Riga, Latvia has designed equipment for the decorative market-place coating Church Icons as seen in the above photographs. AMC E Mail: mail@amc-techcoatings.com |

|